Track safety keeps railway engineers awake at night. One breach in perimeter fencing could delay dozens of trains. A single piece of windblown debris might damage critical signals.

Maintenance crews need quick access while keeping trespassers out.

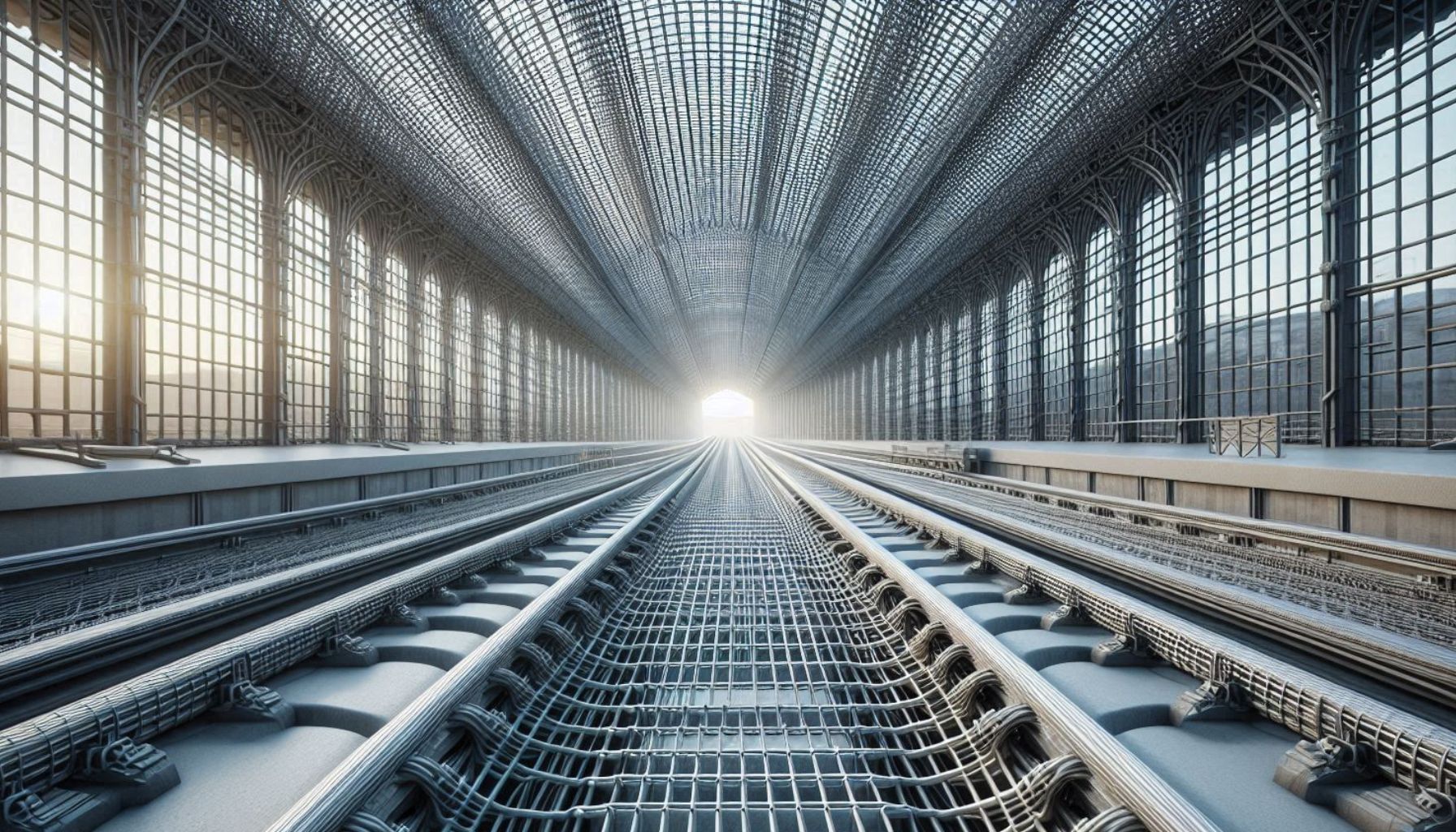

Meaning: railways need security that works smarter, not just harder. And that’s where 3D welded mesh changes the game.

Stone throwing near schools used to mean constant fence repairs. Regular barriers bend or break, leaving gaps until maintenance crews arrive.

3D welded mesh tackles this differently.

The deeper mesh patterns catch projectiles before they reach the tracks, absorbing impact instead of failing under it.

When heavy storms blow debris around, the open structure lets smaller items pass through harmlessly while catching anything big enough to cause damage.

Snow slides off instead of piling up, preventing the structural strain that topples standard fencing.

Rush hour at major stations tests any security system. Passengers push through bottlenecks, creating pressure points in standard barriers.

3D mesh panels change crowd dynamics naturally. The see-through design reduces anxiety in packed spaces.

People flow more smoothly when they can see their whole route. Security teams spot developing issues earlier through the mesh.

When emergencies happen, concealed exits open quickly without creating permanent weak spots in the station’s security setup.

Railway signals can’t afford interference. Metal fencing near signals usually means maintenance headaches and signal distortion.

3D welded mesh solves both problems.

Special coatings prevent electrical interference without compromising strength.

Signal technicians access equipment through dedicated panels that don’t weaken the overall barrier.

The mesh structure itself protects cables and connections from tampering while keeping them accessible for repairs.

Maintenance crews waste hours dealing with awkward access points. Standard security barriers make quick repairs nearly impossible.

3D mesh changes this equation entirely. Purpose-built access panels create stable work platforms when opened.

Crews reach equipment faster without compromising security.

The entire system supports both planned maintenance and emergency repairs while keeping unauthorized people out.

Power distribution along railways needs special protection. Standard fencing conducts electricity, creating hazards for maintenance workers.

3D welded mesh incorporates grounding points and insulated sections that protect both equipment and personnel.

The framework includes clear marking for high-voltage areas without blocking access for repairs.

Power systems stay secure without turning maintenance into an obstacle course.

Railways often divide communities physically. Traditional security barriers make this separation worse.

3D welded mesh helps bridge this gap. The see-through design maintains connection between divided neighborhoods.

Built-in passages allow authorized crossing points that stay secure.

Local authorities get dedicated access for emergency services without creating permanent gaps in railway security.

Railway safety demands solutions that solve multiple problems at once. SK Weldedmesh offers barrier systems that protect infrastructure while supporting efficient operations.

Our welded mesh solutions adapt to each railway’s unique challenges, from urban stations to remote tracks.

When safety can’t be compromised but operations need to stay efficient, advanced welded mesh delivers both.

Get in touch with us to know more.